In today's increasingly competitive market for brands, a small detail can also be the key to standing out. For example, a custom lanyard with a unique logo is not only practical, but also conveys corporate culture or brand image. Today we will learn the story behind this potential marketing tool.

The charm of thermal transfer technology: why it is an ideal choice for lanyard customization

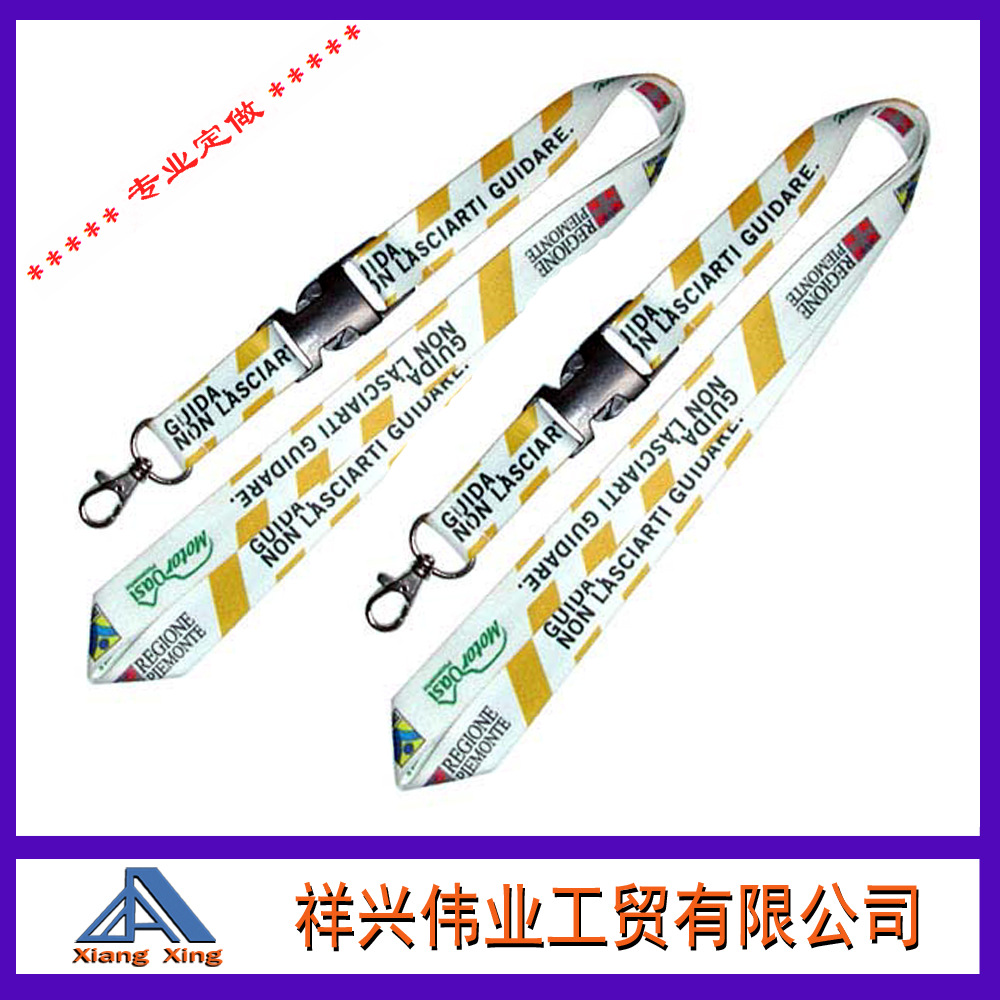

When it comes to customized products, many people first think of whether the printing effect is clear and lasting. The lanyard made of advanced thermal transfer technology is particularly prominent in this regard. It accurately transfers the pattern to the surface of the fabric, maintaining bright colors and high resolution even after multiple washes.

the journey from scratch: revealing the whole process of lanyard production

Each custom lanyard is the result of a team of professionals. Starting from the initial customer demand communication, the designer will design the appropriate layout according to the VI system of the enterprise. Then enter the sample proofing stage to confirm the specific parameters such as width, thickness and material selection. Finally, there is the large-scale production link, where we can see the efficient operation of automatic equipment to complete a series of processes such as cutting and sewing.

Diverse Design Styles: How to Choose the Best Lanyard Style for Your Brand

Different activities may correspond to the opposite demand orientation. Business meetings tend to be simple and generous in image shaping, so you can choose simple and elegant background color and bronzing words as the main elements to form the overall visual language. For outdoor sports events, the feeling of vitality is more emphasized. At this time, you may as well try bold color contrast or add interesting illustrations to enliven the atmosphere.

The secret weapon of quality assurance: an in-depth understanding of the factory's quality control system

In addition to aesthetics, durability is equally important. In order to ensure that each batch can meet the expected standards, manufacturers will implement a strict quality inspection process. This includes, but is not limited to, raw material procurement inspection, online real-time monitoring of defect problems, and finished product sampling to form a closed-loop management mechanism to minimize the probability of defective products flowing out.

New flexible ordering experience: one-stop service from small batch trial to mass production

considering that the actual situation of start-up enterprises or individual users may not need to stock up in large quantities every time, many suppliers now provide extremely humanized solutions-that is, supporting the gradual expansion from small-scale test orders to meet all business expansion needs. This model greatly reduces the risk cost of initial cooperation while enhancing the efficiency of the trust infrastructure between the two parties.

Real Case Sharing: See how other companies have successfully used custom lanyards to enhance their brand image

Let's take a look at some successful examples! A well-known international technology company has specially ordered a limited commemorative version of employee identity tag hanging products for its annual developer conference, and has skillfully integrated the outline line features of its latest generation of products into which participants can't help but compete for collection. Another local chain gym has also launched a member-specific welfare program with the help of this service to encourage more people to actively participate in activities such as the fitness clock-in challenge to create a win-win situation.